About the MBK Wall

Seismic resistance

Monolithic structure, resistant to earthquakes and disasters.

Fire resistance

A1 resistant material, maximum fire safety.

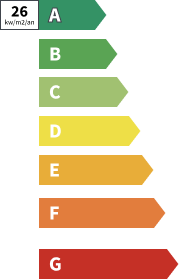

Thermal and acoustic insulation

Thermal and acoustic comfort, energy efficiency A+++

Fast construction

Prefabricated product, execution time reduced by over 60%.

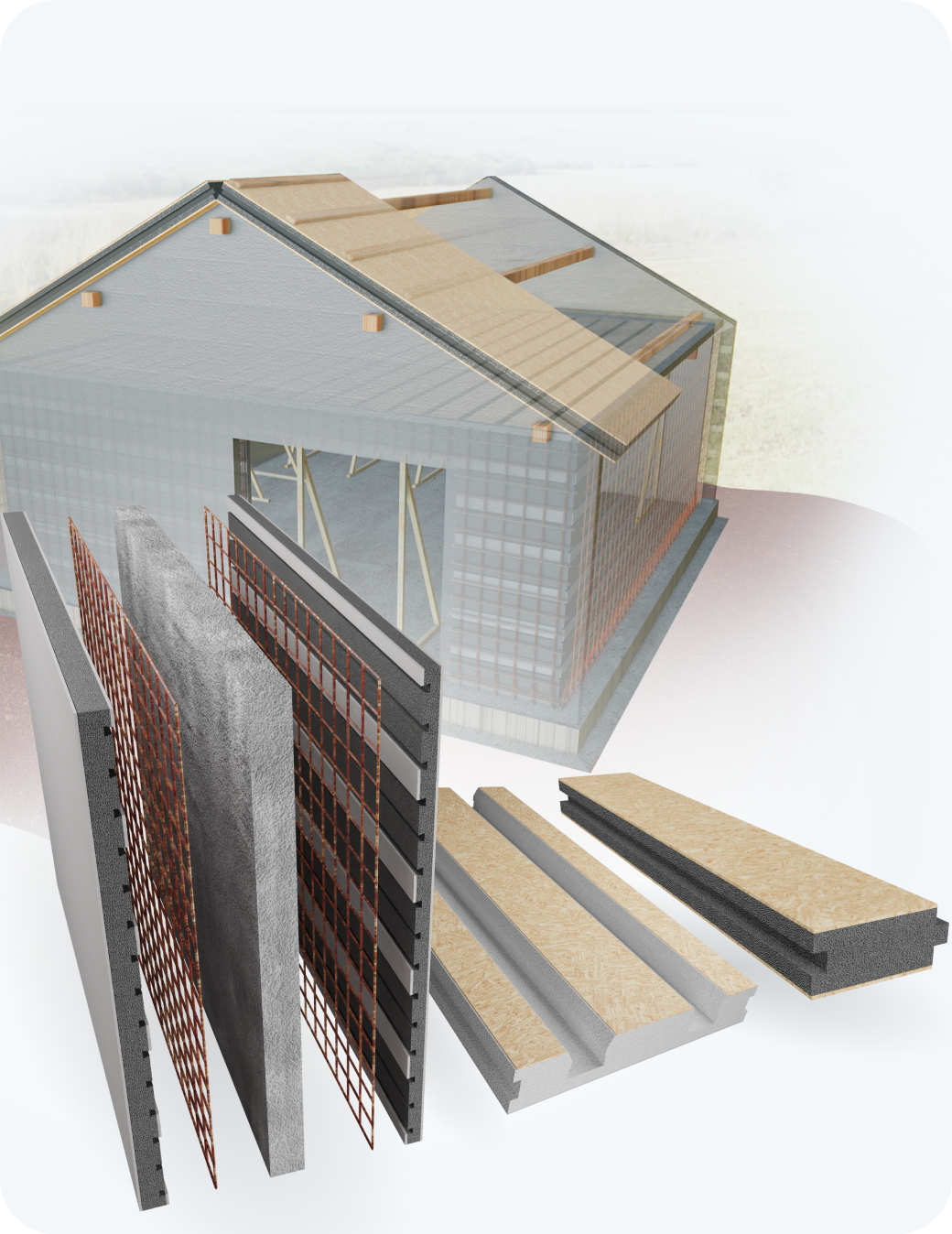

System of assembly

Finishes

Exterior and interior finishes.

Once the MBK walls from Polistibrick are installed and the concrete is poured, they are ready for finishing in a simple and efficient way, even faster than traditional systems. Any material compatible with concrete adheres perfectly to MBK, without the need for additional treatments.

For ventilated facades, the fixing is extremely quick, being done directly into the fibrocement boards, without the need for complex anchoring systems.

Decorative plaster

Thin or thick

Brick, decorative stone

Masonry or applied

Cladding

Quick fixing without profiles or complex fastenings.

Tinci plaster

Applied manually or mechanically.

5-in-1 system

Less labor, fewer human errors, more safety and perfection.

- Masonry

- Exterior and interior insulation

- Air tightness

- Acoustic insulation

- Finish included